refers to a comprehensive system designed to operate factory processes without human intervention.

This platform leverages artificial intelligence (AI) to enable smart decision-making, automation, and optimization of operations.

Additionally, it incorporates digital twin technologies, which create virtual replicas of physical assets, processes, and systems.

These digital twins allow for real-time monitoring, simulation, and analysis, enhancing predictive

maintenance, improving efficiency, and reducing downtime. Together, these technologies create

a highly efficient, self-operating factory environment.

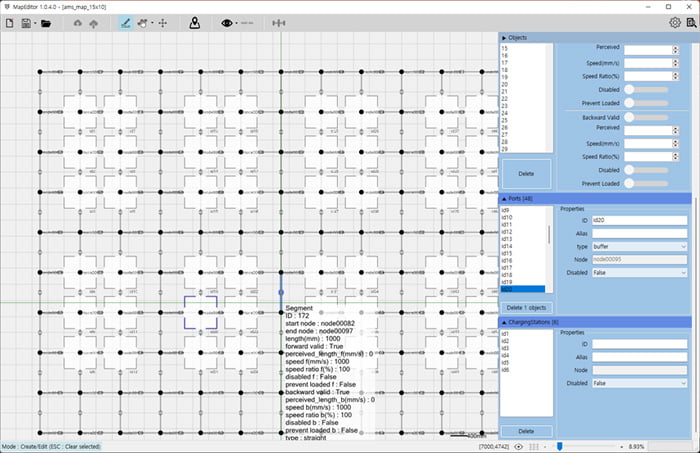

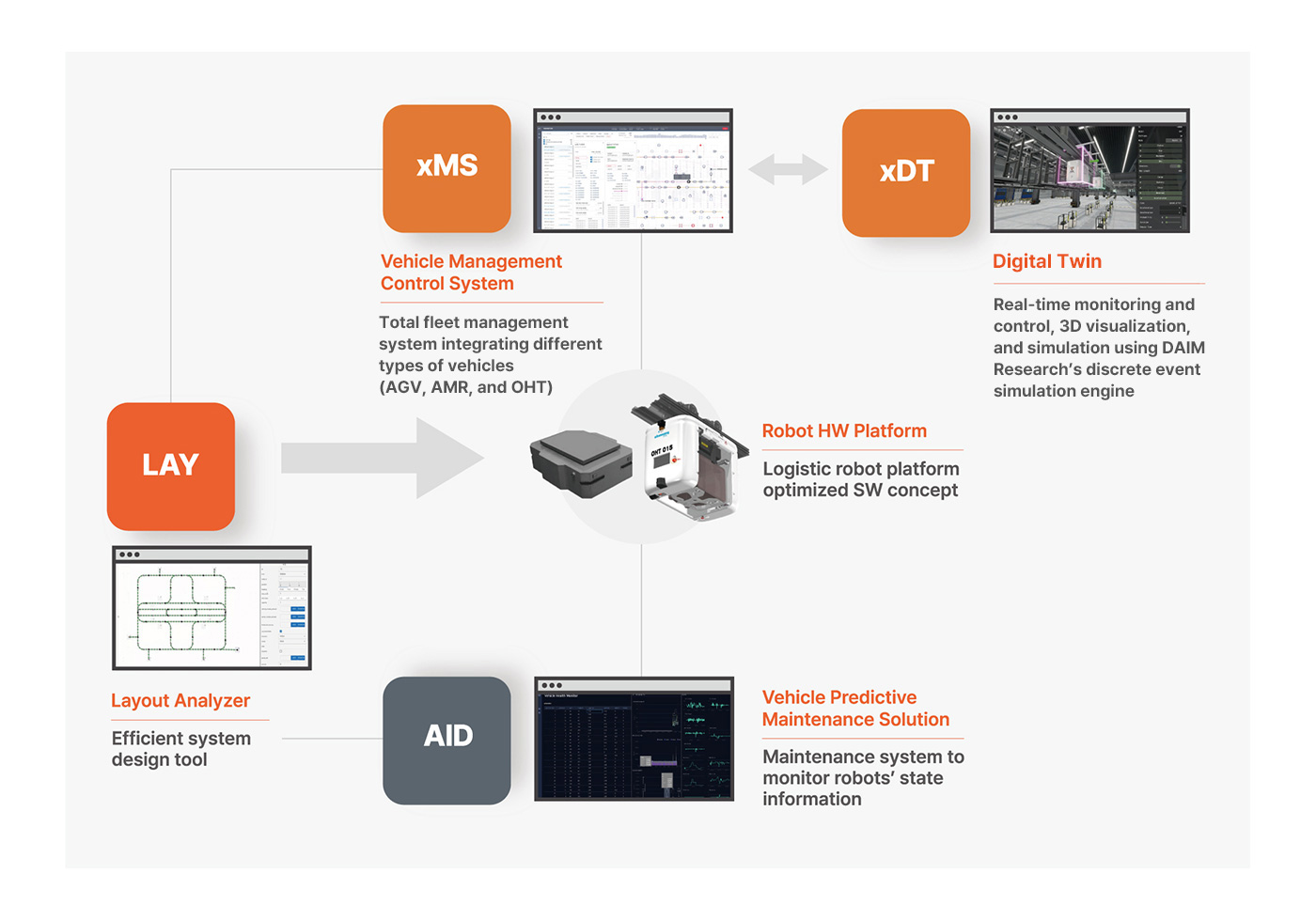

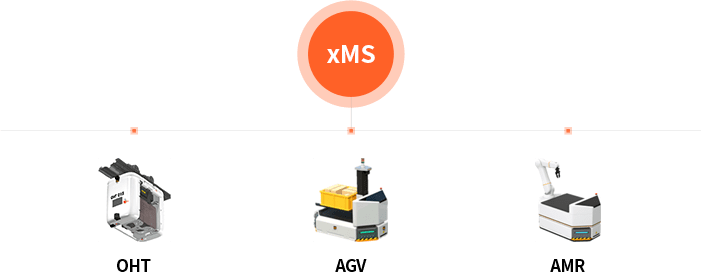

DAIM xMS is an automated material handling system solution that controls/manages fleets of logistics robots based on collaborative intelligence technology.

DAIM xDT is a solution that can virtually simulate various material handling environments in numerous hardware infrastructures that are essential for automated material handling systems.

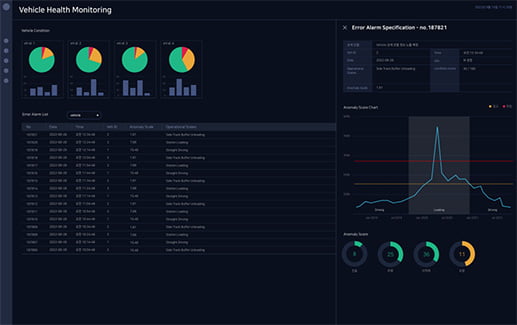

DAIM AID is a solution that monitors the health status of logistics robots at all times to maintain the best condition.

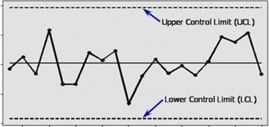

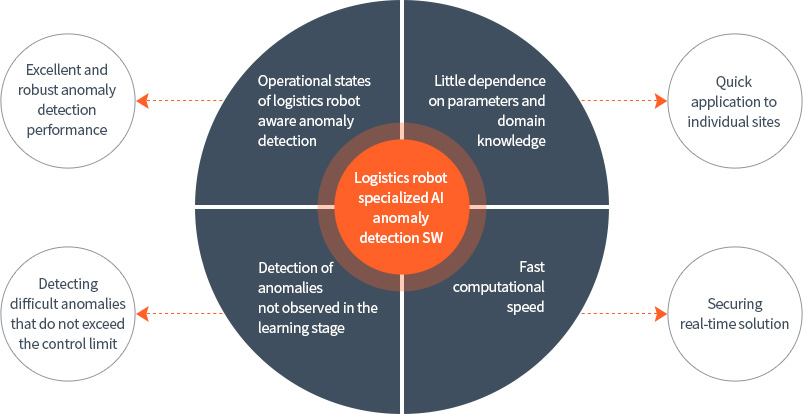

Advanced anomaly detection solutions that understand the operational states of logistics robots and can be applied quickly to individual sites

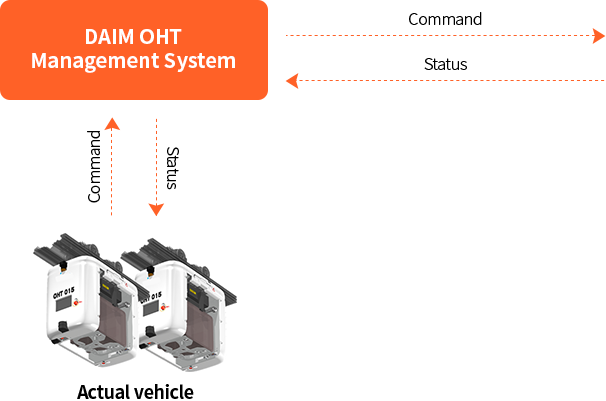

DAIM LAY is an automation solution for the layout design/analysis of automated material handling systems